UV TREATMENT, PORTSMOUTH WATER

Our Role:

Detailed Design, Construction and Commissioning of new UV Treatment Plants for the inactivation of cryptosporidium at the client’s Eastergate, Westergate and Farlington Water Treatment Works. Award of this contract followed detailed re-engineering of the original concept by our in-house design specialists.

The Project

Eastergate & Westergate

On each site, the installation of a UV treatment building to house 2 UV reactors (duty/ standby) with a maximum treatment capacity of 22 Ml/d. The existing borehole pumps are to be replaced with appropriate variable frequency drive pumps. At Westergate the new building will also include a new generator rated at 500 kVA and a bunded diesel tank with sufficient capacity for three days operation.

Farlington

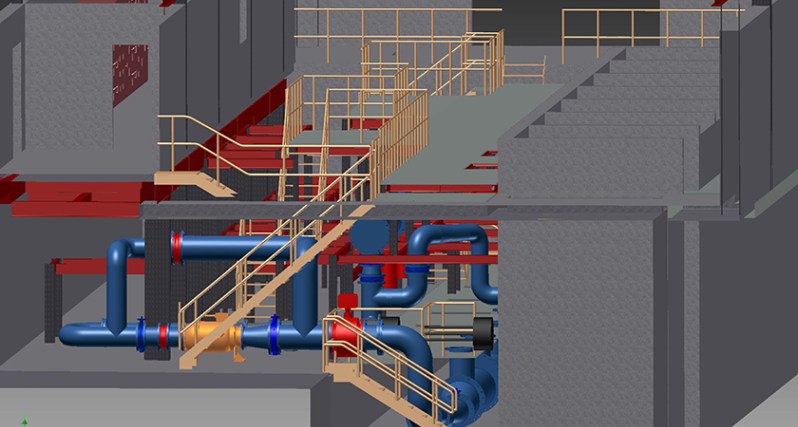

The installation of 5 UV Reactors (four duty with one common standby) interconnected with thin-walled stainless steel pipework. Booster pumping provided to enable treatment at maximum throughput of 100 Ml/d. The scopes also include:

- Modifications to existing chlorine solution dosing lines

- New gas chlorination systems

- New surge control systems (following surge analysis)

- New ICA control & telemetry systems

- New intruder, fire detection & alarm systems

Significant re-engineering of the original design concept by our in-house process, mechanical and electrical design team has introduced these benefits for our client:

- Minimised civil works & avoidance of need for high risk tie-ins

- Ease of operation and maintenance, with similarities with existing membrane plants operation

- Segregated work areas and simplified phased integration to ease continuing operations

- Significantly reduced programme

- Re-use of existing assets – MCC & Main Pipework Headers

- OPEX - Reduced NPV

- Reduced water wastage during lamp warm up phase, UV Lamps more efficient at low flows

Please contact Tim Trant on +44 (0) 2380 665544 or Timothy.Trant@trant.co.uk

Process and Water